Sterilisation for Pharmaceutical Vials

A pharmaceutical vial is a small container, typically made of glass or plastic, used to store and protect liquid, powder, or lyophilized (freeze-dried) pharmaceutical substances. These vials must be sterilized and sealed with a rubber stopper or a screw-on cap, often secured by a metal crimp or seal. They are commonly used for injectable medications, vaccines, or other substances requiring precise dosing. Vials ensure the contents are protected from contamination and maintain sterility until use.

EO Sterilization and Treatment: A Comparative Overview

Ethylene oxide (also known as EO or EtO) is a low temperature gaseous process widely used to sterilize a variety of healthcare products, such as single-use medical devices. Through the use of a vacuum-based process, EO can efficiently penetrate surfaces of most medical devices and its lower temperature makes it an ideal process for a wide variety of materials.

MTT Assay

MTT Assay is a colorimetric assay that measures the metabolic activity of cells as an indicator of their viability. By leveraging the cell's natural enzymatic processes, this assay transforms a yellow tetrazolium salt (MTT) into insoluble purple formazan crystals. These crystals only form in cells with active metabolism, offering a direct correlation between formazan production and the number of living cells.

SVC Nominates Medistri as One of the Top 5 PME Finalists in Suisse Romande

The Swiss Venture Club is renowned for its dedication to promoting and supporting entrepreneurship, innovation and highlighting successful companies for over 20 years throughout the eight economic regions in Switzerland.

Subacute Systemic Toxicity

Subacute Systemic Toxicity is a critical aspect of health risk assessment that evaluates the effects of exposure to harmful substances over a period longer than immediate (acute) but shorter than chronic. This type of toxicity is essential in occupational safety, environmental health, and the development of medical and pharmaceutical products, as it helps to identify potential health risks that emerge from prolonged exposure.

GC/MS Identification of Impurities

Gas Chromatography-Mass Spectrometry (GC/MS) is a powerful analytical technique widely used to identify and quantify impurities in various fields such as pharmaceuticals, environmental studies, and food safety. By combining gas chromatography (GC) and mass spectrometry (MS), GC/MS provides detailed and reliable data crucial for ensuring product purity and safety.

LAL & Bacterial Endotoxin Routine Determination

Routine LAL (Limulus Amebocyte Lysate) testing and bacterial endotoxin determination are crucial for maintaining product safety and quality. By consistently performing these tests, companies ensure that their products meet regulatory standards, protect patient health, and uphold their reputation.

Acute Systemic Toxicity

Acute Systemic Toxicity involves the immediate health risks posed by exposure to harmful substances. It's a critical concern in occupational safety and environmental health, emphasizing the importance of rapid intervention and stringent safety measures.

Identification of Potential Extractables & Leachables

The identification of potential extractables and leachables (E&L) using GC/MS (Gas Chromatography/Mass Spectrometry) is a critical process in ensuring the safety and compliance of Pharmaceuticals and Medical Devices that come into contact with humans.

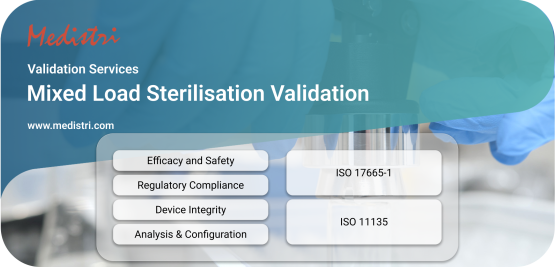

Mixed Load Sterilisation Validation

Mixed Load Sterilisation Validation is crucial for ensuring the efficacy and safety of medical devices. It verifies that sterilisation processes effectively treat diverse loads containing various materials and configurations, meeting stringent regulatory standards. Medistri excels in providing robust validation services, ensuring compliance and reliability in sterilisation practices.