What is a Sterile Barrier System?

A Sterile Barrier System (known as SBS) is often present (and mandated by regulation) in the medical packaging industry. It refers to minimum packaging that prevents contamination and helps to sterilize the finished product. The system must guarantee sterility throughout the whole supply chain from production through to the operation room. ISO 11607-1 specifies the requirements related to the compliance of the packaging for sterilised medical devices, including materials, sterile barrier systems and packaging systems.

ISTA Packaging Standards

At Medistri, you can validate your packaging according to ISTA 2A, ISTA 3A, ASTM D7386, ASTM D4169. Should you fully validate your packaging system or should you simply test one particular characteristic of your sterile barrier system, Medistri laboratory is accredited and highly experienced for the most common test method provided in ISO 11607-1.

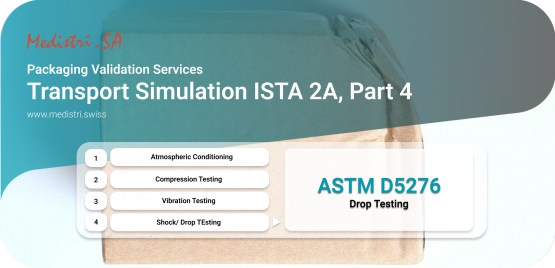

Transport Simulation ISTA 2A, Part 4 - Drop Testing

The ISTA 2A Transport Simulation standard is designed to evaluate ready-to-ship packed items weighing up to 68kg. ISTA 2A standard tests a packaging system’s ability to withstand the physical stress of transportation throughout the product’s supply chain to the final users. The standard is issued by the International Safe Transport Association (ISTA), an organisation devoted to understanding the expectations of secure transport services.

Transport Simulation — ISTA 2A, Part 4 - Drop Testing

The ASTM-D5276 standard test method for drop test of loaded containers evaluates the capability of a container to withstand the sudden shock resulting from a free fall, or the capability of a container and its inner packing to protect its contents during the sudden shock resulting from a free fall.

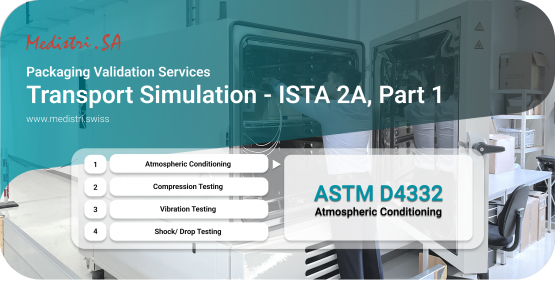

Transport Simulation - ISTA 2A, Part 1 - Atmospheric Conditioning

ISTA 2A standard tests a packaging system's ability to withstand the physical stress of transportation throughout the product’s supply chain to the final users.

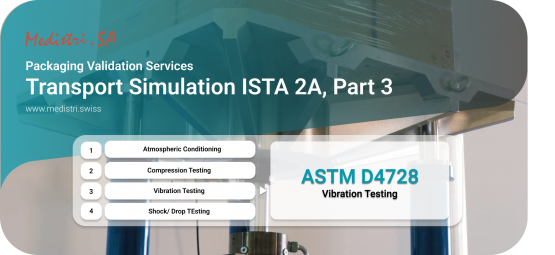

Transport Simulation — ISTA 2A, Part 3 - Vibration Testing

The purpose is to analyse the properties of both the packaging shipping unit as well as the final product, and evaluate if the sterile barrier integrity sealing is not damaged when faced with random vibration inputs.

Transport Simulation — ISTA 2A, Part 2 - Compression Testing

Compression risks are about the most frequent concerns that products and containers experience during the logistics chain.

Bubble Leak Testing for Pharmaceutical Products

Bubble Leak testing is a method of detecting leaks in sealed packaging by visually inspecting them against changes in pressure. Bubble Leak testing is a method of detecting leaks in sealed packaging by visually inspecting them against changes in pressure.